Defects that occur on the surface or on the inside of parts throughout any manufacturing process may have a strong impact on the quality, stability and functionality of the part or the product. This happens, for instance, during the casting process in the automotive industry or during the production of plastic parts in medical technology. As these defects occur in an unpredictable manner, random sample testing is not enough to guarantee high quality of all parts. The solution: 100% inspection or metrology in production – with automated inline CTs of the ZEISS VoluMax family to detect and measure internal defects and structures with high speed.

You have issues meeting cycle times when inspection large castings? ZEISS VoluMax 9 flash is the optimal solution for automated 100% inspection of large parts at high speed. The specially developed detector, which is twice as large, allows you to scan e.g. engine blocks up to 30% faster – 24/7 and without any required cooling in between the scans. High throughput and cycle times of less than 60 seconds are therefore not a problem anymore.

Detect defects reliably inside components without having to sacrifice maximum throughput? This is possible with the ZEISS VoluMax F1500 thunder computer tomograph, which is the first of its kind to be fully integrated into the production line, allowing the fastest 100% inspection.

ZEISS 在線 CT 掃描機可在生產過程中 100% 檢驗已加工的塑料部件和輕量化金屬組件–即使在惡劣的生產環境中也是如此。該 CT 掃描機會自動輸出測量結果是否合格,進而挑出異常的工件。進行 CT 連續檢測過程中,系統可以捕獲及儲存大量不同的產品特征。

許多塑料、金屬和復合材料組件的 CT 檢驗項目已采用 ZEISS VoluMax 系統,例如:ZEISS VoluMax CT 掃描機已用于檢驗塑料部件的尺寸穩定性、檢查汽缸蓋內是否有空腔或型砂殘留,并也已用于檢驗安全氣囊是否正確安裝。ZEISS VoluMax CT 解決方案也適用于 100% 在線檢驗和隨機樣本的在線大量檢測。

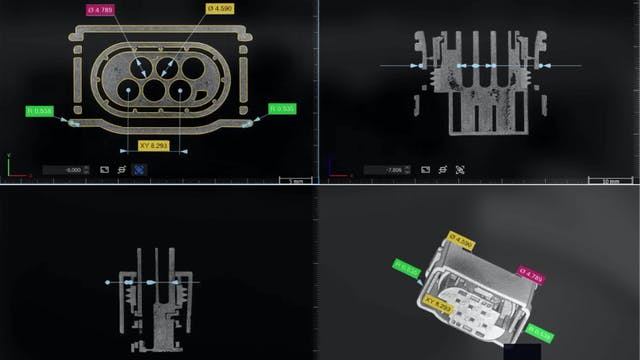

Analysis of a medical housing made of metal for cavities

With ZEISS software, you can use the ZEISS VoluMax CT systems efficiently and exploit their full potential. The ZEISS Automated Defect Detection (ZADD) software uses the CAD model to automatically detect, localize, classify and evaluate whether there are any defects within your components that will impair their quality after processing. Defective components are automatically sorted out to save the costs of unnecessary further processing. The ZEISS PiWeb data management software recognizes repeated occurrence of defects, which allows early intervention in the casting process and thus reduces scrap and costs.

A significant advantage of computed tomography is that it can replace several costly individual tests. Several smaller components can be recorded in one scan and automatically evaluated with regard to dimensional accuracy. This enables a high throughput in production.

Software for the analysis and visualization of industrial computed tomography